The Process of Making Stained Glass

byMaster Craftsman Anatoli Balukh

|

|

The Process of Making Stained GlassbyMaster Craftsman Anatoli Balukh |

| HOME > STAINED GLASS > Anatoli Balukh > PROCESS |

| In order for everyone to appreciate how much work and skill is required, we have put together an overall tour of what it takes to create stained glass. You will see that this is no easy process. There are no pre-made decals, overlays or hi-tech printers. These works (Click HERE to see them) are created by the hands of Anatoli, a gifted master craftsman in Ukraine. Look at the guide and you will be assured that you are truly getting a piece of "old world" quality art. |

|

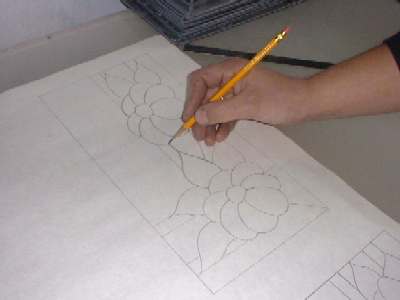

STEP 1 : Layout and ArtworkAnatoli first will draw the pattern full size on heavy weight paper. These are his own designs. Anatollii's background as a trained artist allows him to apply his skills as a painter, iconographer, wood carver and sculptor. He then cuts these pieces out for the next step. |

|

STEP 2 : Glass CuttingUsing the pieces of paper cut from step 1, Anatoli selects the appropriate piece of glass for cutting. He buys his glass from many places in Europe. The type of glass can be very unique and not be found anywhere else. He also selects each piece very carefully to get the desired effect. Not only color, but texture and grain as well. Some pieces are left as the are, others have additional artwork. |

|

STEP 3 : PolishingUsing a wet sander/grinder , the individual pieces are polished to remove burs, sharp edges and also in some instances to add desired effects. |

|

STEP 4 : Air Brush / Art WorkAnatoli applies additional painting or shading using a device similar to an air-brush. This is the difference between everyday art glass and true stained glass. Not many artist or craftsmen can use this technique and make the glass come alive as Anatoli can. |

|

STEP 5 : Baking the GlassUsing a kiln, the stained pieces of glass are then placed for several hours in a kiln, where the stain becomes permanent and part of the glass. This is the most critical part of the process. A hidden flaw in the glass can turn days of work into disappointment. |

|

STEP 6 : Creating the H-Came Lead ChannelTo hold all the glass pieces together, a frame work of lead is used. The lead is shaped into the from of an "H" to surround each piece of glass. In order to assure uniformity of the channel, Anatoli has created his own machine to form the lead to his specifications. |

|

STEP 7 : Dry Fit AssemblyUsing a copy of his layout as a guide, Anatoli assembles the panel of individual glass pieces. Each piece is held in place by the lead caning between them. This has to be done very carefully, a cracked piece could start the whole process over again. |

|

STEP 8 : SolderingAnatoli uses an electric soldering iron to painstakingly secure all of the joints. Even a small piece may take several hours. The large aluminum pipe removes the hazardous fumes which is produced by the process. A copper foil is also applied to the exposed surface of the lead. Once all the joints are soldered, the individual pieces of glass now form one complete panel. |

|

STEP 9 : OxidationAnatoli applies an oxidizer to the copper foil. This gives the foil a protective patina which is uniform on the entire piece. |

|

STEP 10 : Final AssemblyThis panel was 1 piece of a larger window. All of the individual panels will be assembled into 1 window with a support frame. |

|

The Final ProductThese panels were installed as part of a custom door.The serious minded and dedicated Anatoli Balukh inspects his work. This is just one example of what Anatoli can do. We can work to your specifications and create something special, affordable and an original work of art. Please let us know what we can do for you. |